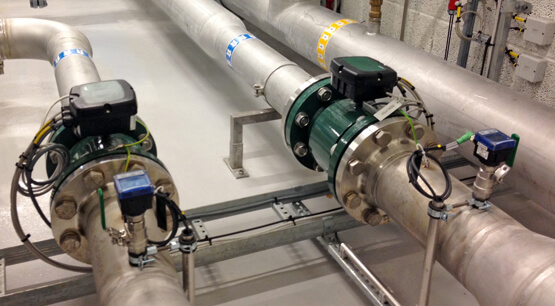

MagFlux is used for flow measurements within wastewater. From incoming liquids with a high content of sludge to outgoing water. In many places, our MagFlux flow sensors are used to keep track of the amounts of wastewater that is moved from urban districts to larger treatment plants. Large DN measurements are often used here, such as DN1000. MagFlux is also MID certified, which means that the flow meter can be used for documentation for invoicing deliveries to or from users, or between plants, as counters cannot be reset.

The MagFlux 7200 series comes with hard rubber lining. This is especially good for liquids that contain solid elements and a certain amount of chemicals such as for example wastewater. If you need to measure liquid with corrosive chemicals or very hot liquids, we recommend MagFlux 7100 with PTFE lining.

The Magflux converter has outputs for both 4-20 mA, ModBus and ProfiBus - depending on the configuration. From the sensor, the signal can be routed up to 1000m in cables. This is convenient in larger sewage pumping facilities. A Magflux display can show data from four converters and sensors.

MagFlux from MJK is used to measure flow from boreholes to the waterworks and document the water that the borehole has delivered. Magflux is also MID certified, which means that the counter cannot be reset. MagFlux is widely used in the network from the waterworks to the end consumer. In many countries, MagFlux is used, among other things, to detect leaks when measuring night flow.

MagFlux 7200 is used for drinking water. This model has a WRAS certificate, which is an approval for drinking water measurements in i.a. England. Magflux 7200 is often used when two waterworks exchange water. As the Magflux sensor measures in both directions, you can easily calculate an overall net result.

MagFlux sensors work well in humid environments, as it can be IP68 secured without problems. You can also choose separate mounting of the converter - up to 50 meters away from the sensor. The sensor has three electrodes built-in and comes with three-point calibration, which gives a very accurate measurement with fluctuations of just 0.25% at as low a speed as 0.2 m/sec. A Magflux display can show data from four converters.

MagFlux can be used for measuring inlet and outlet water, and even for wastewater in sludge tanks. MagFlux flow meters provide accurate measurements of water entering the tanks or of the outlet water discharged via a filled pipe system. The sensor has three electrodes built-in and comes with three-point calibration. This gives a very accurate measurement with fluctuations of just 0.25% at as low a speed as 0.2 m/sec.

The Magflux converter has outputs for both 4-20 mA, ModBus and ProfiBus - depending on the configuration. The converter can be moved up to 50 meters from the sensor. Furthermore, the signal from the converter can be carried up to 1000m to the display - this is convenient for larger aquaculture facilities. The converter can be IP68 secured and thus withstand being constantly immersed in water (max. 10 meters VS) if it is to be mounted in a very humid environment. A Magflux display can show data from four converters and sensors.

If you need to measure flow in very heated water or wastewater with corrosive chemicals, we recommend MagFlux 7100 with TPFE lining. This liner is made especially for process fluidswater. MagFlux is even MID certified, and, since the counters cannot be reset, the flow meter can be used to document invoicing of deliveries to or from users, as well as between systems,.

Magflux is supplied with electrodes in stainless steel, Hastelloy, platinum or titanium - with which almost any requirements can be met. The Magflux converter has outputs for both 4-20 mA, ModBus and ProfiBus - depending on the configuration. The converter can be moved up to 50 meters from the sensor. Furthermore, the converter signal can be carried up to 1000 meters to the display, which is convenient for larger facilities. A Magflux display can show data from four converters and sensors.